areview the safety data sheets for each of your molding and casting materials, then make and compare test casts with each of them

design a mold around the stock and tooling that you'll be using, mill it (rough cut + (at least) three-axis finish cut), and use it to cast parts

Both the processes are closely related or say they are some how one and the same thing depending on hoe you do it. Both the processes involves pouring of molten metal into a mold/die which will take the shape of cavity mold or die on solidification.

The basic difference between moulding and casting is the method by which molten metal is poured. In moulding the metal is poured under pressure but in casting ut doesn't requires any external pressure because of low viscosity of metal which facilitate it to move easily under gravitational force.

At this point i wantd to know the difference between injection molding and die casting The process of making a part is basically the same whether you are using die casting or injection molding. You create a die or mold in the form of the part you want to create. You then liquify the material and use extreme pressure to inject it into the mold.

Design and casting

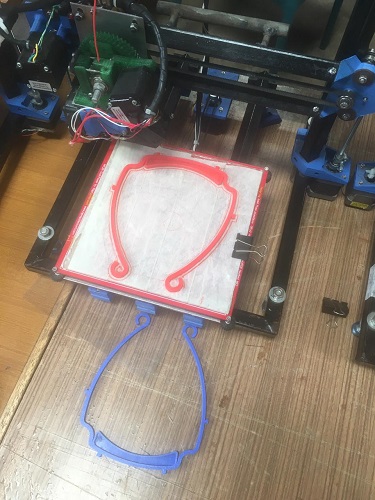

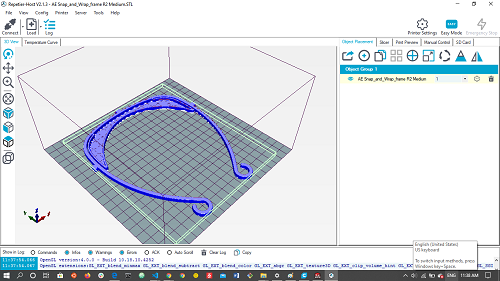

after being involved actively in designing and printning face shields using 3D printer this week i decided to design a mold of one of the designs mold and see if it can be use to produce masively.

here the files used

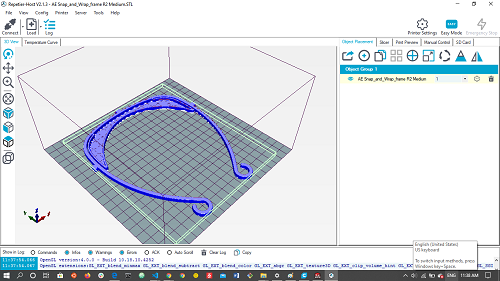

Design Filethis are the processes involved

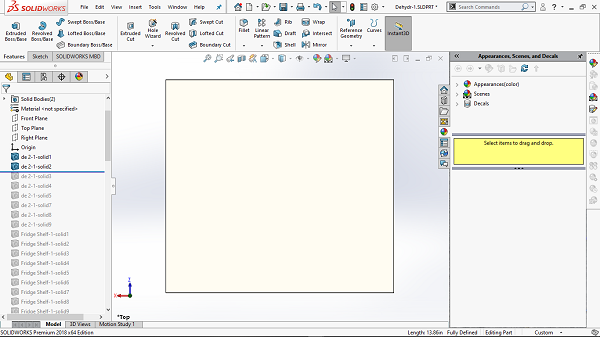

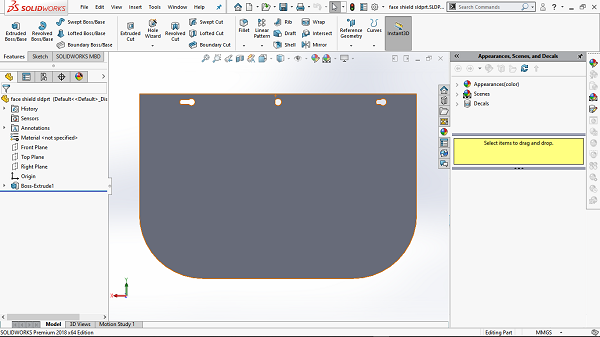

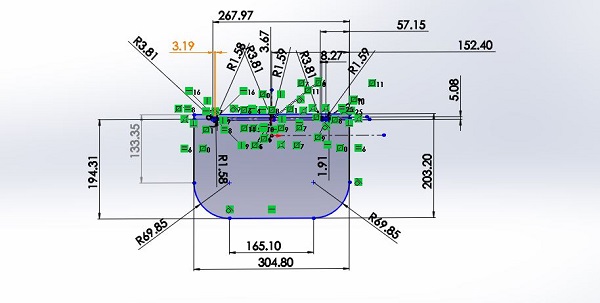

i decide dto use solidworkd to design my mold

this i decided to go with the same dimentions as used by various designs of the same

the following are the dimentions as used

the final product was as follows(to be expected) after molding

its a continuous process that am still developing